Did you know that potato peels and butternut pomace can be turned into biodegradable materials for agriculture?

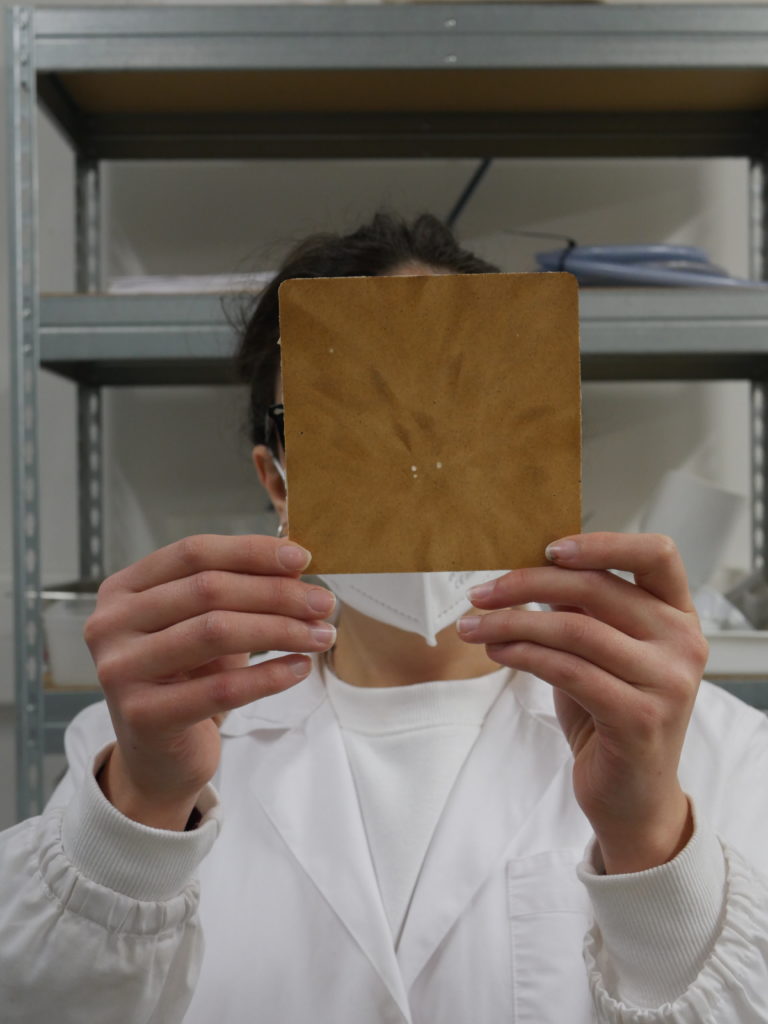

Picture: Biodegradable plate (PHBV/Butternut) freshly pressed and controlled.

My name is Tatiana Coutand and I’m a second-year PhD student at the University of Montpellier. Along with my supervisors, Stéphane Peyron and Hélène Angellier-Coussy, I’m part of the ePOP team (eco-efficient Polymeric and Organic Packaging) at the Joint Research Unit IATE IATE (Ingénierie des Agropolymères & Technologies Émergentes).

Our team’s mission is to develop sustainable alternatives to conventional plastics, specifically for the agriculture and agri-food sectors, to help promote a circular economy.

My thesis focuses on using agricultural residues like potato peels, tomato pomace, and butternut pomace to create bio-based and biodegradable biomaterials. We use a frugal innovation approach, which means we work with end-users—in this case, farmers—right from the start. This ensures the materials we develop have only the essential properties needed, making the process more efficient and user-focused.

One of the main challenges we face is the potential for contaminants like phytosanitary substances to remain in the agricultural waste. To address this, we’ve developed a “challenge test.” We intentionally contaminate the residues to see how well our processes can remove these substances, ensuring the final product is safe to reintroduce into the soil.

Why is it important?

Plastics are everywhere in agriculture, from plant pots to mulch films. However, they break down into persistent particles that contaminate the soil and food production. My research provides a solution by developing sustainable materials made from agro-residues, which are often overlooked as a renewable resource. By using this sustainable resource, we’re not only creating a new product but also adding value to the agricultural supply chain.

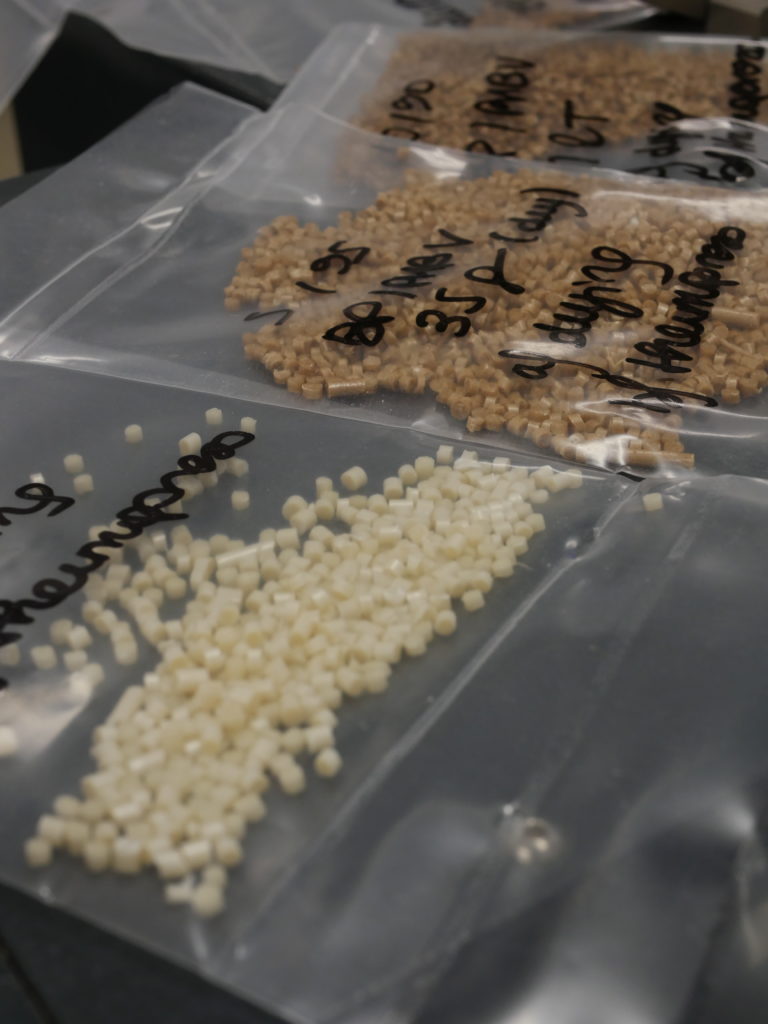

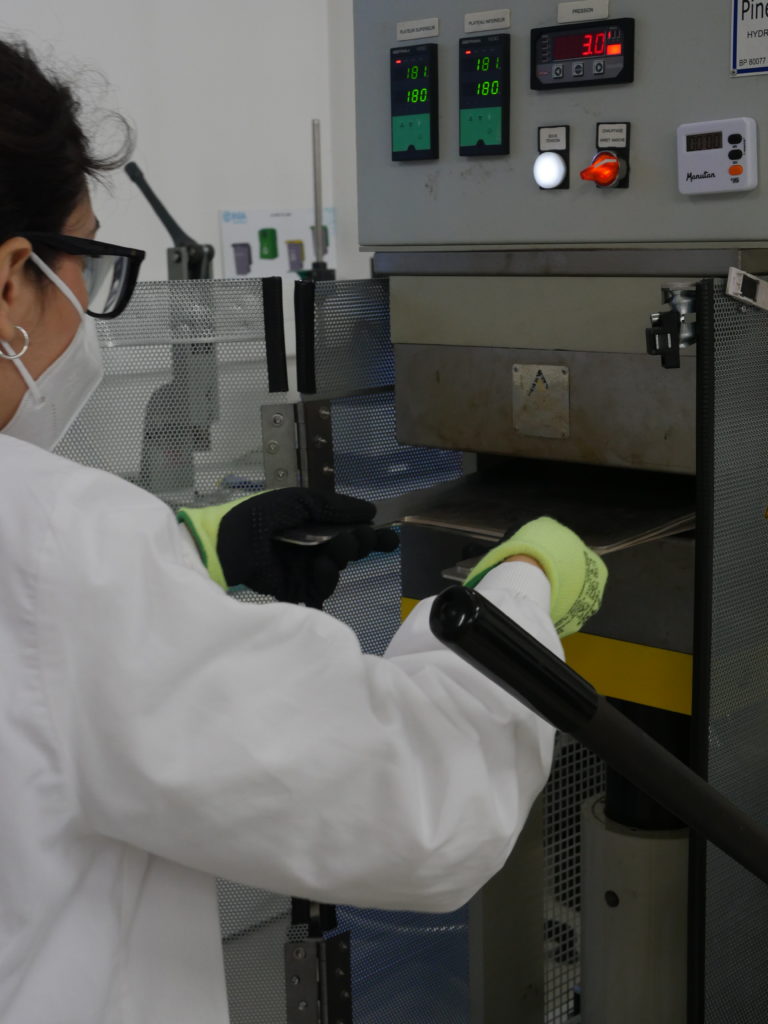

As part of the Agriloop project, we work with a range partners, including the University of Roma Sapienza, who produce the PHBV (polyhydroxybutyrate-valerate), a type of biodegradable polymer from potato peels. We then incorporate finely ground butternut squash pomace into the PHBV to create biocomposites. For this, we work with the FCAC (Federació de Cooperatives Agràries de Catalunya), which supplies us with the butternut pomace. An hydraulic press is used to create dense, uniform pieces of this biocomposite material, like the small, square-shaped biodegradable plate you see here.

The resulting materials are biodegradable, lightweight, and potentially suitable for applications such as packaging, horticultural products, or single-use items.

Key findings and impact

Our research has shown that we can create biocomposites with up to 30% butternut squash pomace. These materials can be injection moulded to create rigid items, which could one day replace conventional plastics.

The best part? When these new materials biodegrade, they don’t leave any persistent particles behind. The carbon simply returns to the soil, leaving no waste or soil contamination. This helps make use of a renewable and sustainable resource that is often seen as waste.

By using this resource, farmers can get involved from the start in designing biodegradable materials that fit their specific needs. Substituting conventional plastics with these bio-based and biodegradable materials can help farmers meet sustainable farming standards. This, in turn, makes it easier for them to earn eco-labels or certifications, giving them access to new, higher-value markets.

An hydraulic press is used in the processing of PHBV (polyhydroxybutyrate-valerate) blended with butternut pomace to create small, square-shaped biodegradable materials. In this process, the PHBV polymer is mixed with finely ground butternut pomace, a fibrous agricultural by-product, to enhance the material’s sustainability and reduce reliance on pure biopolymer. The mixture is then placed into a mold and subjected to controlled heat and pressure using the hydraulic press.

This compaction forms dense, uniform biocomposite pieces with defined square shapes. The resulting materials are biodegradable, lightweight, and potentially suitable for applications such as packaging, horticultural products, or single-use items.

What’s next?

Our next steps are to develop and produce rigid items like plant pots and vine clips. These items will be rigorously tested under real-world conditions to ensure they are durable and perform as needed. We’ll also be exploring how other lignocellulosic residues can be incorporated to improve the final products.

Stay updated !

Want to learn more about our journey from farm side-streams to sustainable materials ? Follow us on LinkedIn for more insights. You can also reach out to us with any questions at: agriloop-it@inrae.fr